Universal Touchscreen Embedded Control Platforms

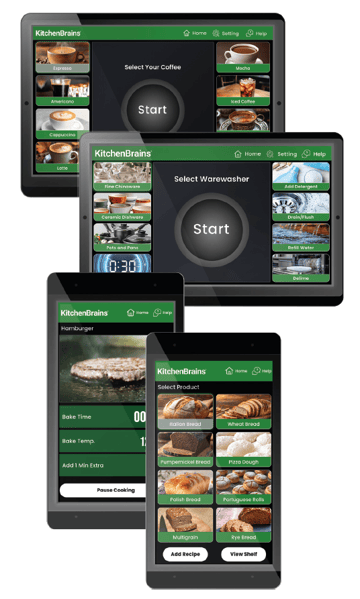

The VTC Series touchscreen control platform revolutionizes embedded commercial appliances by integrating the functionality of multiple independent devices into a single, intuitive touchscreen interface.

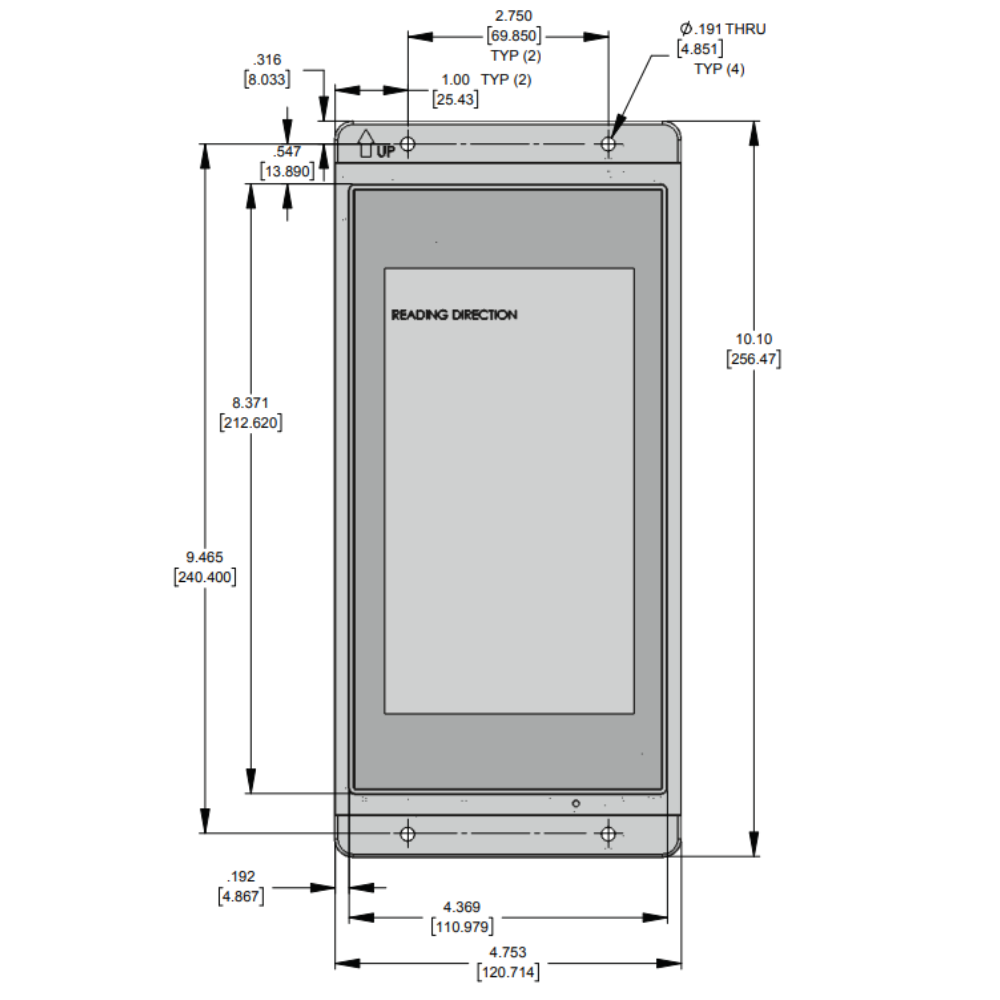

Available in 5”, 7”, 8”, and 10” touchscreen sizes, the VTC Series offers OEMs a highly configurable and adaptable solution for modernizing their product lines.

This platform simplifies appliance design, reduces assembly costs, and enhances the end-user experience, ultimately improving food quality and operational efficiency.

With advanced features like PCAP touchscreen technology, flexible connectivity options, and powerful diagnostic capabilities, the VTC Series sets a new standard for commercial appliance control.

Product Information & Manuals

Product/Spec Sheet

Click To ViewJackson Case Study

Click To View

Embedded Touchscreen Control Features

Configurable Logic: Customized logic based on specific appliance requirements ensures optimal performance and seamless integration.

Flexible Connectivity: Offers multiple connectivity options, including Bluetooth or Wi-Fi, enabling data transfer, remote monitoring, and integration with kitchen management systems.

Enhanced User Experience: PCAP touchscreen display technology supports video capability, allowing users to view illustrations, training videos, and intuitive operation.

Streamlined Manufacturing: Reduces labor at assembly by eliminating point-to-point wiring and reducing inventory costs through a multi-configurable control platform that is compatible across multiple appliance types.

Designed for Commercial Appliance Manufacturers

User Interface & Control

PCAP touchscreen simplifies operation, minimizes training, and reduces errors.

Adaptable software allows use across various types.

Programmable access modes with password protection for various personnel.

Bright graphical LED-backlit display supports multiple languages.

Real-time clock enables accurate timekeeping and data logging.

Customizable graphics allow branding and UI personalization.

Control & Performance

Precise temperature control with the proprietary SmartStat™ algorithm ensures accurate cooking temperatures and improved food quality.

Programmable duty cycles manage multiple processes, including time, temperature, motors, dampers, circulating pumps, solenoids, actuators, etc.

Heat soak or recovery logic prevents operation until the appliance recovers from a cold start or prior cycle.

I/O & Integration

The flexible I/O board option supports direct connection to the appliance, featuring four Thermistor or RTD temperature inputs, four 24V DC digital inputs, and twelve 24V DC relay driver outputs.

Communication protocol options include RS232/RS485 for flexibility and integration with a variety of input/output boards.

Connectivity

Bluetooth or Wi-Fi, enabled data transfer, remote monitoring, and integration with kitchen management systems.

USB or Micro SD Card data transfer simplifies updates, diagnostics, data logging, and HACCP or parameter updates and retrieval.

Optional IoT connectivity enables reporting and alerts for automated kitchen systems.

Diagnostic & Maintenance

Advanced diagnostics streamline troubleshooting and reduces downtime.

Energy savings features with optional Setback, Service Maintenance Scheduling (SMS), and auto repair alarm contribute to energy efficiency.

Brownout protection with optional configuration safeguards against power fluctuations.

Simplify Costs & Inventory

Reduced labor costs by eliminating point-to-point wiring.

Single, multi-configurable control reduces SKUs and simplifies inventory management.

Specifications

Appliance Applications:

- Ovens (Convection, Combi)

- Fryers

- Holding Units

- Rethermalizers

- Braising Pans

- Beverage Dispensers

- Ware-washers

- Ranges

- Commercial Laundry

- Post Mix

- Smokers

- And More

Certifications:

- IEC-60730

- Global Compliance