Engineered for Your Brand:

Smarter Controls, Less Waste, Better Food Quality

Design controls that fit your menu, your kitchens, and your labor profile—so every shift delivers the brand promise while cutting waste and elevating food quality.

For multi-unit brands, consistency isn’t an aspiration—it’s table stakes. We engineer embedded controls and connected monitoring that translate your culinary standards into repeatable, role-friendly workflows across every location.

From cooking and holding to refrigeration and food safety, our systems guide teams to do the right thing, the right way, every time—no matter who’s on the line.

-

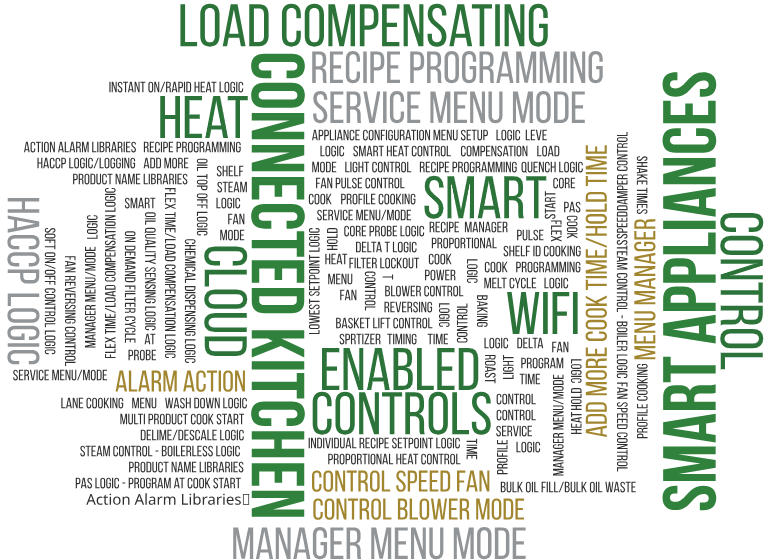

Menu-adaptive control logic

Configure time/temperature profiles, cook curves, and holding rules to the specifics of your menu—including daypart, LTOs, and regional variations. Update once; deploy everywhere. -

Process-specific workflows

Engineer steps, interlocks, and alarms around how your kitchens actually run—fry, bake, hold, chill, thaw, proof, clean—so execution matches your standards at volume. -

Operations & throughput orchestration

Align back-of-house execution with real-time demand and capacity. Connect cooking, holding, and refrigeration data to the rest of your tech stack to minimize waste and out-of-stock moments. -

Labor-aware UX

Role-based screens, icons, and prompts make complex tasks simple for teams with varied experience levels. Training time drops; compliance rises.

Build the controls you need to delight customers and move the P&L

-

Reduce waste with precise controls, automatic setback and maintenance prompts, and connected temperature monitoring that prevent overcooking, over-holding, and product loss.

-

Improve food product quality via compensating algorithms and smart temperature control that keep specs tight in the real world. Guests get the same great product, shift after shift.

-

Protect the brand at scale with digitally enforced recipes, HACCP-ready data, and cloud visibility across every market.

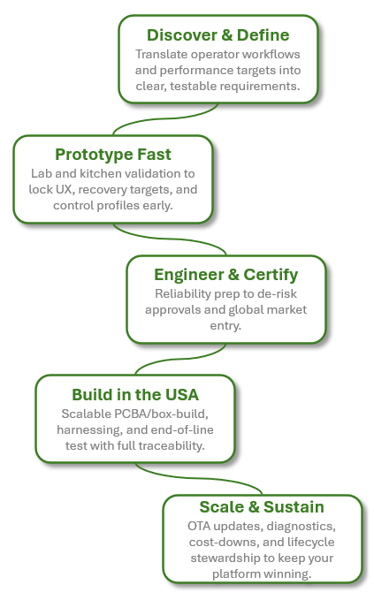

One Team, Full Stack: Design, Engineer & Build

Our supply chain options provide resilience against disruptions, ensuring uninterrupted access to essential materials and components.

Inventory Management:

Reduce overhead costs with our dock-to-stock programs, streamlining inventory management and enhancing operational efficiency.

Global Reach:

Expand your reach effortlessly with our global certifications and shipping capabilities, all supported by our proficiency in international logistics.

Deliver your brand promise of customer satisfaction with ongoing product support and technical assistance.

Short Lead Times:

With extensive single and multi-parameter appliance control platforms available, our short lead times are unmatched.

Engineering Expertise:

Leverage our decades of industry experience and extensive logic library of innovation to gain valuable insights and support throughout the development cycle.

Future Proof Your Business:

Collaborate with us to define your product technology roadmap, incorporating product capabilities and planning to deliver cutting-edge technology like connected kitchen integration and IoT.

Efficient Manufacturing:

Enjoy shorter lead times and the convenience of our manufacturing facilities, allowing optimized production and comprehensive product testing, ensuring reliability and functionality at every stage.