Reliable, Precise Heat Control, Easy-to-Integrate Power Management

The Voltage Inverter Board delivers a dependable, high-performance solution for precise, fixed-output heat control in commercial kitchen appliances. Purpose-built for rugged, high-demand environments, this compact and durable board simplifies power delivery to resistive heating elements, ensuring stable, user-adjustable heat across a wide range of foodservice applications.

Ideal for warming stations, hot-holding units, and any equipment requiring consistent thermal regulation, the board’s solid-state architecture offers unmatched reliability and energy efficiency. Its robust design withstands harsh kitchen conditions, including high humidity, heat, and vibration, ensuring long-term performance.

Whether you’re designing next-generation hot-holding equipment or retrofitting legacy systems for improved efficiency, the Voltage Inverter Board delivers simplified integration, precise thermal output, and is built restaurant-tough from the inside out.

Product Information & Manuals

Product/Spec Sheet

Click To View-1.png?width=486&height=300&name=Copy%20of%20Voltage%20Inverter%20%20Board%20(600%20x%20300%20px)-1.png)

Maximize Output with Purpose-Built Features

- Duty-cycle AC control of resistive heating elements for fixed, precise output.

- The onboard potentiometer allows for quick adjustments within a tamper-proof, preconfigured range.

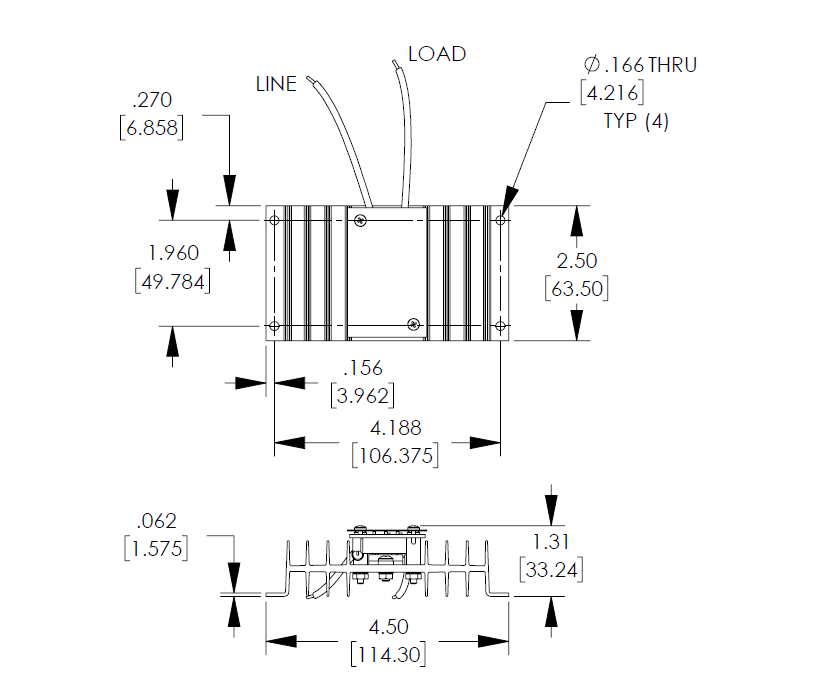

- Compact, flanged heat-sink design mounts securely in appliance control compartments.

- Solid-state TRIAC switching ensures long-life, maintenance-free operation.

- Simplified two-wire inline installation between the power source and the heating element.

- Input range 208–240 VAC, output controllable between ~150–195 VAC; supports up to 25 Amps.

- Spike protection built-in (minimum 4 kV) to safeguard timers and controls.

Key Benefits That Make a Difference

Built Restaurant-Tough and Reliable: Designed for high-heat, high-demand commercial kitchen environments with solid-state durability and consistent performance.

Streamlined Assembly: Pre-configured output simplifies calibration and reduces setup time on the line.

Fewer Points of Failure: Solid-state design improves long-term reliability, reducing warranty claims and service calls.

Versatile Integration: Flexible form factor and control compatibility make it easy to incorporate across multiple appliances.

Thermal Efficiency: Efficient power conversion minimizes excess heat, easing thermal design constraints in tight enclosures.

Built to Solve Real-World Challenges

Product Differentiation with Advanced Heat Control

Modern solid-state design enables precise, fixed-output heating that sets your appliances apart.

OEMs can stand out in a competitive market by integrating a heat control solution that delivers consistent, reliable performance without bulky mechanical components. The sleek, compact design enhances product aesthetics and functionality, supporting next-gen appliance innovation.

End-User Satisfaction with Reliable, Consistent Heating

No temperature swings, no recalibration—just dependable performance that operators can trust.

The Voltage Inverter Board ensures steady, user-adjustable heat ideal for hot-holding and warming applications.

It improves food quality and safety, reducing user frustration and lowering the risk of customer complaints or returns.

Speeds Production with Drop-In Simplicity

Compact footprint, minimal wiring, and no external sensors mean faster assembly and easier integration. Enabling reduced build times and labor costs.

The board’s plug-and-play design makes it easy to scale across multiple product lines with minimal re-engineering—boosting throughput and flexibility on the production floor.

Reduce Costs Through BOM Simplification

One integrated board replaces multiple analog components—fewer parts, fewer headaches.

Streamlining the bill of materials not only cuts procurement and inventory costs but also minimizes potential failure points. This allows OEMs to build smarter, leaner, and more cost-effective appliances.

Brand Trust with Long-Term Reliability

Solid-state construction stands up to the rigors of commercial kitchens.

OEMs gain peace of mind knowing their products are backed by a robust, low-maintenance solution built to endure heat, grease, and vibration. Fewer service calls mean happier customers and a stronger brand reputation.

Frequently Asked Questions

Voltage Inverter Board

-

What types of heating elements is the Voltage Inverter Board compatible with?

The board is designed specifically for resistive heating elements, making it ideal for applications like hot-holding units, warming stations, and food-safe enclosures. It delivers a stable, fixed-output power level optimized for these loads, ensuring consistent thermal performance.

-

How easy is it to integrate the board into existing appliance designs?

Very easy. The board has a compact footprint and requires minimal wiring. With no need for external sensors or complex programming, it can be quickly integrated into both new and legacy designs, minimizing engineering time and tooling changes.

-

Does the board require calibration or software configuration?

No. The Voltage Inverter Board is pre-engineered with fixed output settings, eliminating the need for on-site calibration or software setup. This reduces production time and simplifies field installation and maintenance.

-

Can the board withstand high-heat or grease-heavy environments?

Yes. It is engineered specifically for the harsh conditions of commercial kitchens. The solid-state design ensures long-term durability and stable performance, even in environments with heat, vibration, and airborne grease.

-

Is the board manufactured domestically?

Yes. The Voltage Inverter Board is made in the USA, supporting fast lead times, consistent quality, and avoiding overseas shipping delays or tariffs. This also allows for easier collaboration and custom design support if needed.

Specifications

- Mounting: Flanged aluminum heat-sink packs securely in the control cavity

- Max Ambient Temp: 70 °C (158 °F), 90% RH (non-condensing)

- Input Voltage: 208–240 VAC, 60 Hz

- Output Voltage: Programmable 150–195 VAC via potentiometer

- Maximum Load Current: 25 Amps (consult factory for higher needs)

- Switching: Solid-state TRIAC-based

- Transient Surge Protection: 4 kV minimum

- Certifications: UL-listed control board (Ref. 213-50778-XX)

- Shipping Weight: Approx. 5 oz

- Operating Life: Solid-state reliability