Flexible multi-process control for demanding commercial kitchen appliances.

The Vision Series Multi-Process Controls from Kitchen Brains® deliver unmatched reliability, configurability, and performance for manufacturers designing advanced foodservice and commercial appliances.

Built to manage multiple inputs and outputs with precision, these controls reduce SKUs, streamline operations, and improve food quality and consistency across a wide range of applications.

Featuring easy software reconfiguration, enhanced diagnostics, and advanced service tools, the Vision Series empowers OEMs to cost-effectively innovate and differentiate their appliances while extending equipment life and lowering support costs.

Product Information & Manuals

Product/Spec Sheet

Click To DownloadPopular Appliance Applications:

- Automated Fryers, Grills, Broilers

- Microwave/Combi/Convection Ovens

- Laundry

- Waste Disposal/Pulpers

- Post Mix

- And More

Features of Vision Series Embedded Controls

-

Energy-saving functions: Setback mode, Service Maintenance Scheduling (SMS), and auto repair alarm

-

FAST.Nav™ programming keys for simplified set-up and end-user use

-

Flexible multi-process management: time, temperature, motors, valves, pumps, detergent dispensing, and more

-

Configurable product and alarm libraries for recipe and process customization

-

Bright graphical VFD display with multi-language support to reduce operator errors

-

Highly adaptable platform with FAST.Flex™ time and comprehensive diagnostics

-

Optional real-time clock and HACCP connectivity for compliance and reporting

Manufacturer Benefits of Vision Series Controls

Lower Development Costs: Reduce SKUs with a configurable control platform adaptable to multiple appliances.

Simplified Serviceability: Built-in diagnostics and FAST.Edit® configuration tool cut downtime and service expenses.

Enhanced Food Quality: Consistent results across recipes and appliances with precise process management.

Extended Appliance Life: Energy-saving features and monitoring protect critical components.

Improved Operator Experience: User-friendly keys and clear VFD display minimize training and errors.

Vision Series Solves OEM and Operator Challenges

SKU Proliferation

Managing different controls across appliances raises costs. Vision’s multi-configurable platform reduces SKUs and simplifies manufacturing.

Recipe Management

As menus evolve, consistent results are harder to achieve. Vision ensures repeatable food quality with multi-stage recipe profiling and lockout functions.

High Service Costs

Equipment downtime impacts profitability. Vision’s advanced diagnostics, auto alarms, and FAST.Edit® reconfiguration reduce support costs.

Operator Errors

Training crews on multiple interfaces increases errors. Vision’s intuitive FAST.Nav™ keys and VFD graphics simplify use across appliances.

Energy Waste

Unmonitored equipment drains resources. Vision integrates setback modes and duty cycle flexibility to cut energy use and prolong appliance lifespan.

Compliance & Reporting

Food safety regulations require traceability. Optional HACCP connectivity integrates Vision into automated kitchen reporting systems.

Frequently Asked Questions

Vision Series

-

What types of appliances can the Vision Series control?

Vision supports fryers, ovens, grills, laundry, beverage dispensers, waste pulpers, and many more.

-

How does Vision reduce manufacturing costs?

Its configurable platform allows one control to serve multiple appliances, lowering SKUs and manufacturing expenses.

-

Does it support HACCP compliance?

Yes, with optional communications modules, Vision can integrate with HACCP and automated kitchen systems.

-

What energy-saving features are included?

Setback mode, SMS scheduling, and programmable duty cycle management all help cut energy use.

-

How durable is the Vision Series?

Engineered for harsh environments, Vision operates at up to 158°F (70°C) and 95% non-condensing humidity.

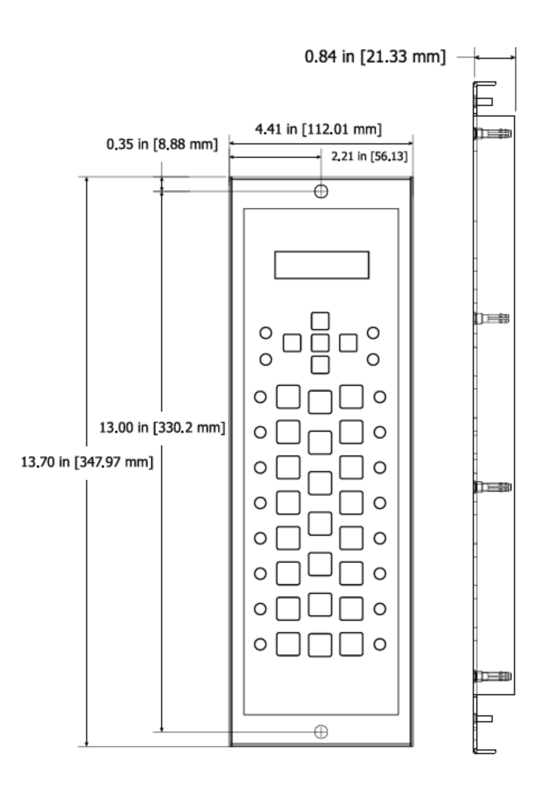

Specifications

-

Input Voltage: 24VAC ±10%, 50/60Hz

-

Power Consumption: 40VA

-

Temperature Probe Inputs: Up to 4 (1K RTD or 91K Thermistor)

-

Digital Inputs: (4) 24VDC (e.g., door or load switches)

-

Outputs/Type: Up to (8) 24VDC relay driver outputs for relays, heaters, motors, solenoids, valves, etc.

-

Audible Output Devices: Vertical – 95dB Piezo @ 5ft; Horizontal – 85dB speaker

-

Temperature Range: 32–550°F (0–287.7°C)

-

Temperature Accuracy: ±5°F/°C

-

Display: Graphical VFD, 20 red LEDs

-

Programming Keys: Vertical – 28 membrane keys; Horizontal – 32 pushbuttons

-

Noise Protection: 4000V minimum

-

Environmental Conditions: 158°F/70°C, 95% non-condensing humidity

-

Shipping Weight: Vertical ~4 lbs (1.81 kg); Horizontal ~3 lbs (1.36 kg)