Efficient, Simple and Scalable Embedded Controller

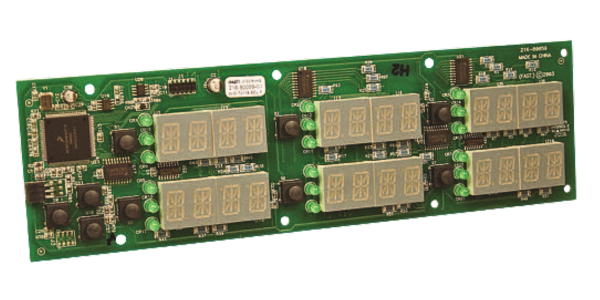

The MDT Series is a powerful embedded commercial appliance controller designed to streamline and optimize the manufacturing processes of commercial appliance OEMs. Engineered with precision and flexibility in mind, the MDT Series eliminates the complexity of traditional wiring, simplifies configuration and programming, and enhances operational visibility across the kitchen.

With peer-to-peer communication capabilities and intuitive interfaces, the MDT Series embedded control empowers OEMs to reduce commercial appliance SKU proliferation, providing restaurant operators with smarter, more connected food preparation environments.

Product Information & Manuals

Product/Spec Sheet

Click To Download

Smart Controller Features

-

Eliminates point-to-point wiring, reducing assembly time and labor costs

-

OEMs can standardize on one embedded control model, minimizing SKU inventory complexity

-

Peer-to-peer communication allows seamless timer transfer between units

-

FAST.Edit® configuration software enables fast customization and easy serviceability

-

Unique on-appliance installation supports flexible integration into equipment

-

Real-time status monitoring and audible alerts improve kitchen communication and workflow

-

Displays product names, timers, and alarms from either a preloaded or user-defined library

-

Simple to program and operate

-

Compact 12VDC input voltage for easy appliance integration

One Custom Commercial Controller, Multiple Benefits

Reduce Production Cost: Reduces labor and complexity during appliance assembly

Reduce Inventory: Standardized model simplifies inventory management and speeds production of commercial appliances

Adapability: FAST.Edit® tool enhances product adaptability for multiple equipment models

User Friendly: Minimizes support and training costs with an intuitive interface

Purpose-Built Kitchen Controls for OEMs and Operators

Streamlined Manufacturing Efficiency

Reduce assembly time and complexity by eliminating point-to-point wiring. The MDT Series helps commercial appliance OEMs reduce labor costs and accelerate production timelines, enabling faster time-to-market and higher manufacturing throughput.

Inventory

Simplification

One embedded commercial kitchen control fits many applications. OEMs can minimize part numbers and SKUs by standardizing on a single, adaptable control platform. This consolidation simplifies purchasing, warehousing, and logistics operations.

Enhanced Kitchen Connectivity

Peer-to-peer communication enables smarter workflows. The MDT Series automatically transfers timing functions between units, keeping multi-station operations synchronized and increasing throughput without extra staff input.

Configurable and Service-Friendly

Adapt and update with ease using FAST.Edit® software. Whether it's initial setup or field service adjustments, the MDT Series offers quick configuration and reprogramming, reducing downtime and enhancing flexibility for adapting to changing menus or processes.

Operator-Friendly Functionality

Simple to program, intuitive to use. With customizable displays showing timers, product names, and alarms, the MDT Series reduces training time and minimizes operator error—ideal for high-turnover kitchens.

Real-Time Status and Alerts

Boost kitchen awareness and food safety. With across-the-kitchen status visibility and audible alerts, staff can react quickly to timing cues, improving food consistency, reducing waste, and maintaining service speed.

Frequently Asked Questions

MDT Series

-

How does the MDT Series reduce manufacturing time and labor costs?

The MDT Series eliminates the need for traditional point-to-point wiring, significantly reducing assembly time and labor on the production line. Its streamlined design simplifies integration into appliances and speeds up manufacturing workflows.

-

Can one MDT model be used across multiple appliance types?

Yes. The MDT Series is designed as a universal control platform, allowing OEMs to standardize on one model for a variety of applications. This reduces SKU complexity and simplifies inventory management.

-

How easy is it to configure or update the MDT Series in the field?

Very easy. The MDT Series is fully supported by Kitchen Brains® FAST.Edit® software, which enables fast, on-site configuration and updates—ideal for service teams and quick adaptation to menu or process changes.

-

Does the MDT Series support kitchen-wide communication between appliances?

Yes. With built-in peer-to-peer communication, the MDT Series can transfer timing information between units, keeping stations synchronized and improving kitchen workflow and coordination.

-

What display options are available for operators?

The MDT Series offers flexible display options, including timers, product names, and alarms. It supports both preloaded and user-programmable libraries, ensuring operators have clear, relevant information at a glance.

Specifications

-

Input Voltage: 12VDC

-

Configuration Tool: FAST.Edit® software

-

Installation: On-appliance mounting

-

Communication: Peer-to-peer transfer capability

-

Display: Customizable with time, product names, and alarms

-

Programming: User-friendly, software-assisted or manual

-

Alerts: Audible kitchen-wide alerts for operational efficiency