Reliable time & temperature control, in a compact footprint.

The Kitchen Brains® CTT Series is a robust, mid‑level controller that unifies timing and temperature management for commercial cooking and holding appliances. Designed for manufacturability, CTT reduces point-to-point wiring and consolidates multiple discrete components (timers, buzzers, displays) into a single, compact board—streamlining assembly, shrinking footprints, and lowering BOM and lifetime ownership costs for your customers.

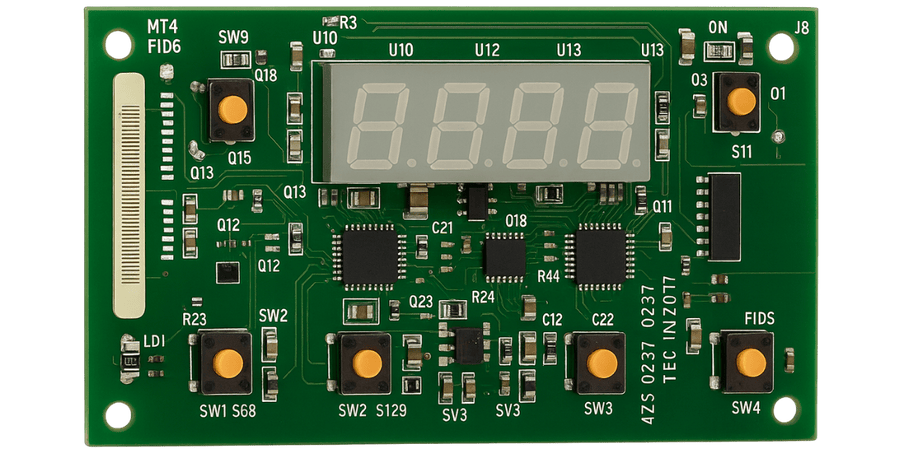

Operators get an easy, 4‑button “touch‑n‑go” interface with large LED time and temperature displays, pre‑alarm/action cues, and audible end‑of‑cycle prompts for consistent results. Configurable device types support single or dual‑zone applications (e.g., grills, fryers, drawer warmers, holding cabinets, ovens), with programmable setpoints, ready bands, hysteresis, melt/cool options, and recipe times to match your appliance requirements.

Product Information & Manuals

Product/Spec Sheet

Click To DownloadOperating Guide

Click to Download

CTT Series Features for OEM Integration

- OEM‑friendly architecture: Reduces labor by removing point‑to‑point wiring; compact size optimizes footprint.

- Unified UI: Large 7‑segment LED time/temperature displays with bright status indicators and four product keys.

- Recipe memory: Four one‑touch product buttons with easy “touch‑n‑go” programming.

- Dual or single zone control: Configurable device types for grills, fryers, drawer warmers, holding cabinets, ovens and more.

- Action, pre‑alarms, & completion alerts: Audible and visual cues for mid‑cycle actions and end‑of‑cycle completion.

- Diagnostics & probe monitoring: Error reporting, software version display, and analysis/diagnostics prompts.

- Energy & process options: Set temperature, melt enable/timing (certain device types), setback/efficiency modes.

- Rugged & compliant: RoHS compliant; designed to operate up to 158°F/70°C ambient.

OEM Benefits of the CTT Series

Faster Assembly & Lower Costs: Fewer parts and simplified wiring reduce build time and overall appliance cost.

Consistent Food Quality: Precision electronic control and clear operator cues minimize errors and variability.

Reduced Support Burden: No recalibration, simple operation, and durable design lowers service calls over the product life.

Platform Flexibility: A single control supports multiple appliance types and zones, simplifying SKUs and training.

Kitchen‑Wide Visibility: Bright displays and alarms provide across‑the‑kitchen status for better coordination.

OEM Challenges the CTT Series Solves

Complex Wiring

Traditional appliances require point-to-point wiring that adds labor, increases assembly time, and creates more potential failure points. The CTT Series integrates timing, temperature, alarms, and displays into a single compact controller, streamlining manufacturing and reducing costs.

Inconsistent Cooking

Manual or mechanical controls often lead to uneven cooking, which impacts food quality and customer satisfaction. The CTT Series uses programmable setpoints, ready bands, hysteresis, and action alarms to ensure consistent, repeatable results across every batch.

Operator Error

In fast-paced kitchens, staff can easily miss steps or cues. The CTT Series combats this with four one-touch product keys, bright LED displays, and audible alerts that simplify operation and guide operators through each cycle, minimizing mistakes.

High Support Costs

Mechanical controls drift over time and require recalibration, driving up service costs. The electronic precision and built-in diagnostics of the CTT Series eliminate recalibration, reduce downtime, and lower total cost of ownership.

Limited Platform Reuse

Managing different controllers across product lines raises training and inventory challenges. With the CTT Series, one configurable platform can support grills, fryers, ovens, warmers, and more—cutting SKUs, simplifying training, and improving flexibility.

Harsh Kitchen Environment

Heat, humidity, and heavy use can quickly wear out sensitive controls. The CTT Series is designed to operate reliably up to 158°F/70°C, with RoHS-compliant durability to withstand the demands of commercial kitchens.

Frequently Asked Questions

CTT Series Controllers

-

What appliances can the CTT control?

Multi‑zone grills, dual/single‑zone drawer warmers, fryers/rethermalizers, holding cabinets, and single‑zone ovens (fan output variant).

-

How many recipes or products can I program?

Four one‑touch product keys with individual total and pre‑alarm times.

-

Does CTT support dual‑zone temperature control?

Yes, selected device types support independent top/bottom (dual‑zone) setpoints and ready bands.

-

What operator feedback does it provide?

Large LED display for actual/set temps and time, status indicators (READY, countdown, DONE), action alarms, and audible alerts.

-

What happens if a temperature probe fails?

The display shows probe error (e.g., “PErr/Prbt/Prbb”) and ends cook cycles with a continuous alarm, prompting service.

Specifications

-

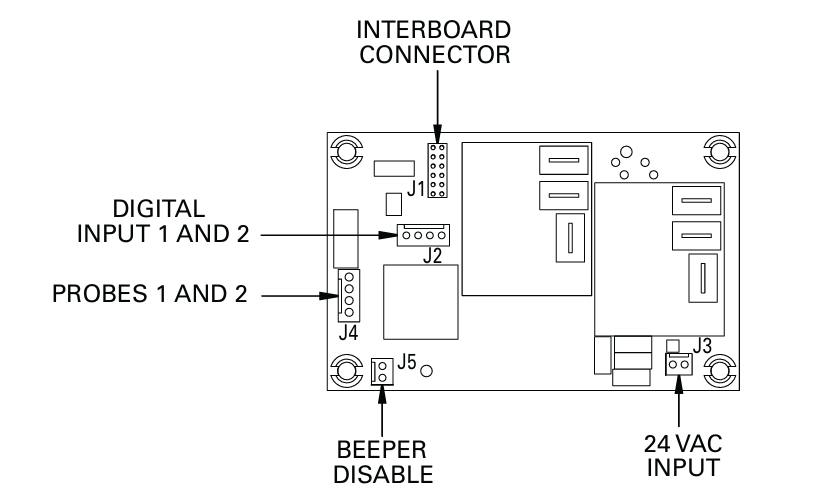

Input Voltage: 24 VAC ±10%, 50/60 Hz; Power: 10 VA

-

Temp Probes: (2) 91K Thermistor or 1K RTD inputs

-

Outputs: (2) Relay, 30A 250 VAC (SPDT)

-

Audible Output: Piezo beeper ~80 dB at 3 ft; beeper disable jumper

-

Control Range: 40–550°F (4–288°C); Accuracy: ±5°; Offset: ±50°F; Hysteresis: 0–10°F programmable

-

Display/Interface: (4) 7‑segment green LED displays; (4) red product LEDs; (4) Product Keys + Temp Key + Program Key

-

Time Format: 00:00 to 9 hr 59 min; HH:MM or MM:SS

-

Programming/Operation: Touch‑n‑go recipe setup; pre‑alarm/action times; DONE alarms; software version display; probe diagnostics

-

Environmental: Designed to operate reliably up to 158°F/70°C ambient; 95% RH non‑condensing

-

Compliance: RoHS; recognized component

-

Shipping Weight: ~0.5 lb (0.226 kg)