Precise, Reliable Multi-parameter Controller

The Kitchen Brains® CH-300 Multi-Parameter Control empowers OEMs to integrate advanced cooking intelligence into their appliances.

This customizable control platform can streamline product development time, reduce labor by eliminating point-to-point wiring, and save on inventory costs.

The compact design, featuring tab-selectable voltage, simplifies integration, and a robust parameter set supports a wide variety of applications that can be embedded across multiple appliances, including broilers, convection ovens, fryers, and more.

With intuitive programming, optional connectivity for HACCP compliance, and proven reliability, the CH-300 enables OEMs to differentiate their products, enhance customer satisfaction, and streamline their manufacturing processes.

Product Information & Manuals

Product/Spec Sheet

Click To Download

CH-300 Multi-Parameter Control Features

- Adaptable to a wide range of appliances, including ovens, fryers, broilers, mixers, dishwashers, and more

- Compact size with on-board transformer and tab-selectable voltage for simplified integration

- Easy-to-use encoder knob or FAST.Nav™ keys for recipe and process programming

- Bright, multi-character graphical VFD display

- Supports multiple languages

- Precise temperature control (140–550°F / 60–287.7°C)

- Multiple configurable outputs for coordinated cooking, holding, motor control, dampers, solenoids, and more

- Optional communication link for HACCP reporting and automated kitchen management systems

- Built-in safety features: Setback™ mode, service scheduling, auto-repair alarms

OEM Benefits of the CH-300 Control

Reduced Development Costs: Pre-engineered, customizable platform reduces wiring, design, and inventory complexity

Enhanced Product Differentiation: Elevate appliance value with intuitive interfaces and connectivity options

Improved Food Quality & Consistency: Precise electronic control ensures repeatable results

Increased Appliance Reliability: Long-life solid-state design rated for millions of cycles

Faster Time to Market: Easily reconfigurable software accelerates OEM appliance development

Manufacturer Challenges the CH-300 Solves

High Development Costs

The CH-300 streamlines development by eliminating point-to-point wiring and offering a pre-engineered, configurable platform. OEMs save on design time, reduce assembly labor, and cut overall R&D expenses.

Product Differentiation

With advanced recipe programming, intuitive displays, and HACCP-ready connectivity, the CH-300 helps OEMs build smarter appliances that stand out from competitors while boosting brand value.

Inconsistent Food Quality

Precise electronic timing and temperature control ensure consistent cooking results every time. Commercial kitchen manufacturers can deliver appliances that improve food quality, reduce waste, and improve customer satisfaction.

Appliance Downtime

Built-in diagnostics, service maintenance scheduling, and auto-repair alarms extend appliance life, reduce service calls, increase reliability, and customer loyalty.

Complex Global Integration

The CH-300’s compact design, tab-selectable voltage, and RoHS compliance reduce the number of SKUs and inventory costs, making global deployment easier.

Time-Consuming Training

User-friendly programming keys, an intuitive encoder knob, and clear status displays reduce operator errors and shorten training time for new users.

Frequently Asked Questions

CH-300 Multi-Parameter Control

-

What types of appliances can the CH-300 control?

It supports ovens, fryers, broilers, mixers, marinators, commercial dishwashers, and many more appliance applications.

-

How does the CH-300 help reduce OEM costs?

By removing point-to-point wiring, using a compact transformer design, and offering software reconfiguration for multiple platforms.

-

Does the CH-300 support HACCP compliance?

Yes, optional communication links provide connectivity for HACCP reporting and integration with automated kitchen systems.

-

What makes the CH-300 user-friendly?

It features a bright, easy-to-see VFD display, multi-language support, intuitive FAST.Nav™ programming keys, and end-of-cycle alarms.

-

What is the operating temperature range?

It maintains precise control from 140–550°F (60–287.7°C), with ±20°F offset and 5°F accuracy.

Specifications

-

Input Voltage: 120/240VAC ±10%; 50/60Hz, tab selectable

-

Power Consumption: 25VA

-

Analog Inputs: (1) 1K RTD or 100K Thermistor

-

Digital Inputs: (2) 24VDC (door/product switches)

-

Outputs: (2) 30A relay SPDT, (2) 10A relay SPST

-

Additional Output: (1) 24VDC PWM (10kHz/20kHz) for relays, solenoids, basket lifts, etc.

-

Audible Output: 95dB piezo alarm at 5 feet

-

Temperature Control Range: 140–550°F (60–287.7°C) ON/OFF & proportioning with ±20°F offset

-

Temperature Accuracy: ±5°F

-

Displays: (4) seven-segment LED, (9) LED indicators, VFD graphical display

-

Programming: Encoder knob or FAST.Nav™ keys (6 keys, rated for 10M cycles)

-

Environmental: 158°F (70°C), 95% non-condensing humidity

-

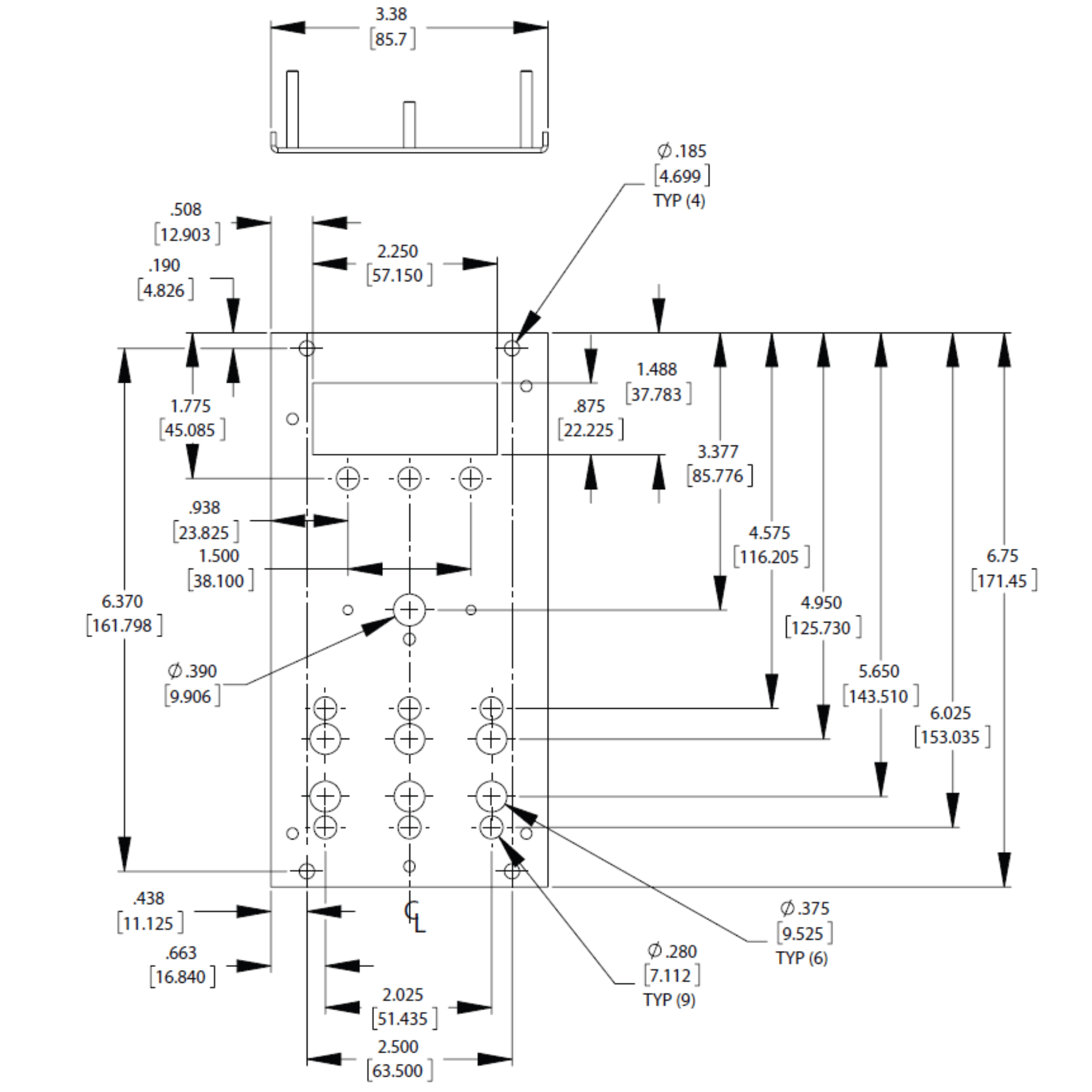

Dimensions: 6.75” h x 3.375” w x 2.5” d; encoder shaft .75” long, 6mm dia.

-

Shipping Weight: 4 lbs. (1.81 kg)